Polyethylene is the most common and widely used plastic across the globe. However, is it right for the kind for your project? Try considering the exceptional characteristics of UHMWPE plastic (Ultra high molecular weight polyethylene), a very tough and durable variant of polythene.

With the wide range of plastics available from UHM manufacturers India, it may be quite difficult to decide which type of plastic would be best suited for your project. UHMW plastic from top UHMWPE manufacturers would be an excellent choice for your project. UHMW plastic from leading UHM manufacturers India has great attributes, but still remains overlooked when it comes to being used as a material in building projects. You must know more about this type of plastic and consider it.

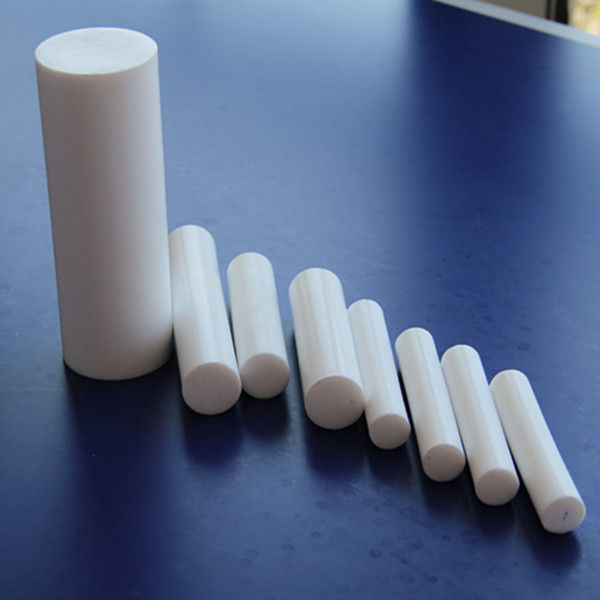

Characteristic features of UHMWPE sheets and rods

Here are the major characteristic features of UHMWPE sheets and rods from top UHMWPE manufacturers:

- It is chemically resistant to most acids, bases, electrolytic attacks, and organic solvents.

- It has a high molecular weight ranging from 3-6 million.

- It does not melt or flow like molten liquid.

- It is known for its extreme hardness and durability.

- It is extremely lightweight.

- It has a strength to weight ratio greater than steel. (8-15 times)

- It shows exceptional resistance to stress.

- It has a low coefficient of friction.

- It is non-toxic and non-staining.

- It is odorless and tasteless.

- It has a high tensile and high impact strength.

- It shows high abrasion resistance.

- It is highly resistant to abrasion. (Some UHMWPE sheet from UHM manufacturers India is almost 15 times more abrasion resistant than carbon steel.)

- It produces a stronger and more consistent product.

- It possesses a long life and is known for its longevity.

- It has natural lubrication, therefore, does not require artificial lubrication.

- It is resistant to moisture and water.

- It shows corrosion resistance as well.

- It also shows the property of acoustic impedance (reduces noise and vibration).

- It is easy to fabricate.

- It is resistant to UV radiation and microbes.

Major Applications of the UHMWPE sheets from UHMWPE manufacturers

There is a great demand for UHMWPE sheets produced by UHMWPE manufacturers from India. The main reason behind this is that the UHMWPE sheets and rods find application in diverse industry verticals.

UHMWPE sheets from UHMWPE manufacturers are approved for use in the food industry and medical industry by the Food and Drug Administration (FDA) and the US Department of Agriculture (USDA).

Food industry

- UHMWPE plastic from UHMWPE manufacturers is widely used in food services applications.

- Work surfaces, cutting boards, countertops, and cabinets are some places where UHMWPE sheets from UHM manufacturers India are used.

- One of the main reasons why UHMWPE sheets are extensively used in the food processing and beverage industry is that it is resistant to chemicals and corrosion.

- The use of sanitizers and cleaners will not affect the food service cabinetry if UHMWPE sheets are used.

- It also makes the cabinets and food contact surfaces visually appealing and smooth.

Ballistics

- UHMWPE from leading UHM manufacturers India is also used in the manufacture of body armor and armor plating.

- The main reason behind the use of UHMWPE in ballistics is the high impact resistance.

- Also, being light in weight, they are easy and comfortable to wear for a long time.

UHMWPE from UHM manufacturers India is used in the manufacture of:

- Truck trays and bins

- Ropes and cordage

- Prosthetic implants

- Cryogenic components

- Machinery parts

- Medical equipment

Regardless of your project, it is crucial to use the right materials for it, so that you get the desired results. UHMWPE sheets from UHM manufacturers India have many useful properties. This makes a UHMWPE sheet a preferred choice for many industrial applications.